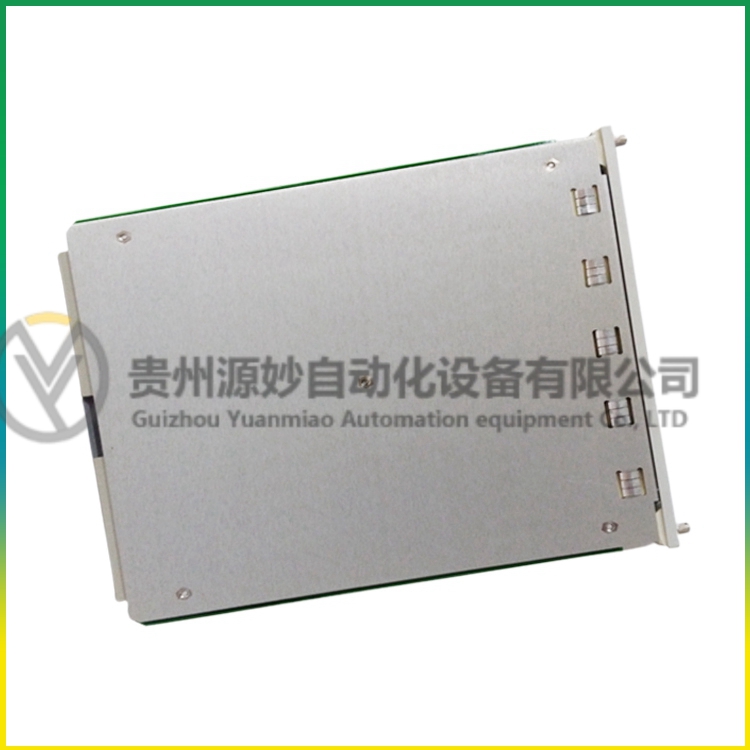

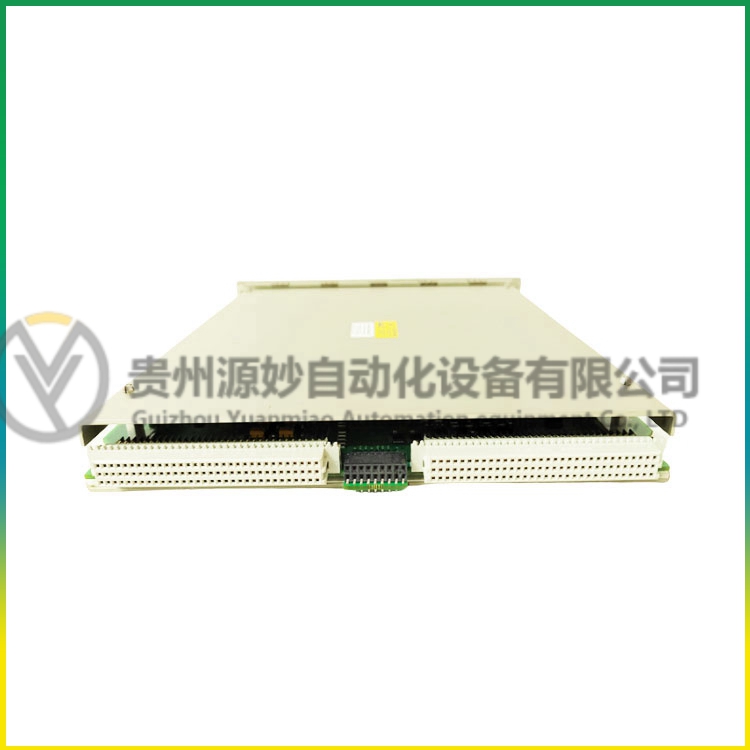

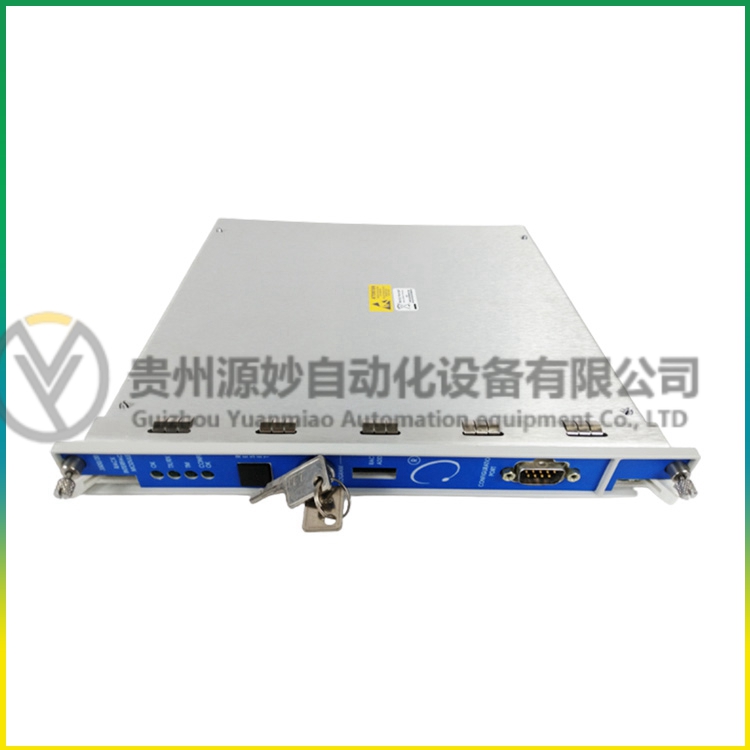

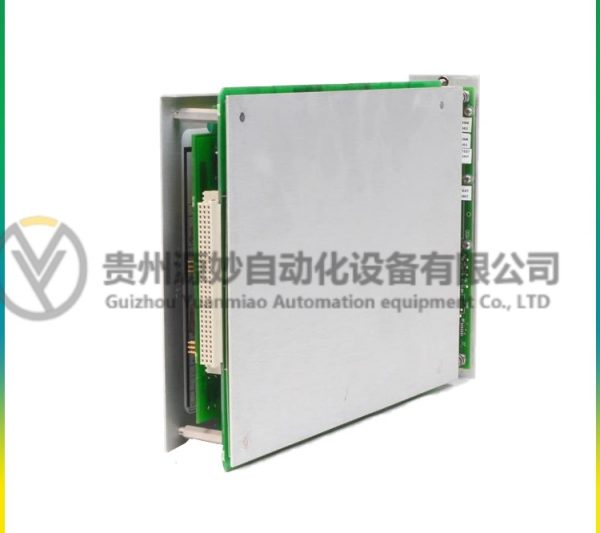

The Bently 3500/70M is a reciprocating pulse/speed monitor primarily used in the reciprocating compressor solution package to monitor the crankcase and crosshead vibration of the compressor. The monitor is a 4-channel monitor capable of receiving input from seismic sensors and adjusting the signal to obtain various vibration measurements. It then compares the adjusted signal with a user-programmable signal to provide an alert function.

The main purpose of the monitor is to provide basic machine information for operation and maintenance by continuously comparing the parameters of the monitoring of the configuration alarm set point of the mechanical protection drive alarm. Each channel typically modulates its input signal into various parameters called «static values», and users can configure alarms as well as a set point for each active static value and any two danger set points.

In addition to the core functions, the Bently 3500/70M May have other features and functions such as high stability and reliability, ease of installation and operation, multiple communication interfaces, and more. These features enable the monitor to be adapted to various industrial environments and meet different application requirements.

In practical applications, the Bently 3500/70M is widely used for vibration monitoring and fault diagnosis of various compressors and mechanical equipment. It can help users find abnormal vibration and potential faults of equipment in time, so as to take appropriate maintenance measures to avoid production interruption and equipment damage.

Overall, the Bently 3500/70M is a powerful and stable vibration monitor that provides a reliable solution for the health monitoring and maintenance of industrial equipment.

Эта статья была опубликована на официальном сайте компании generation automation LTD LTD в вашем штате:www.robots-automation.com

Reviews

There are no reviews yet.